- #First robotics labview programming tutorial how to#

- #First robotics labview programming tutorial update#

- #First robotics labview programming tutorial driver#

- #First robotics labview programming tutorial code#

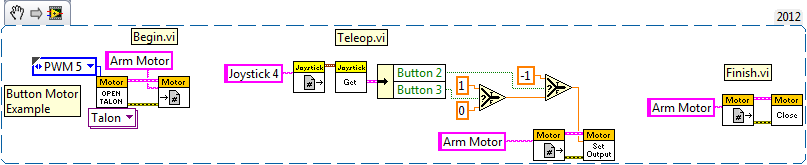

This is useful for initialization code that doesn’t belong to a particular subsystem. BeginĬalled once when robot code first starts. VIs used for robot code that is not part of a subsystem that are not used very often. This serves as a custom replacement for the WPILib RobotDrive VIs.

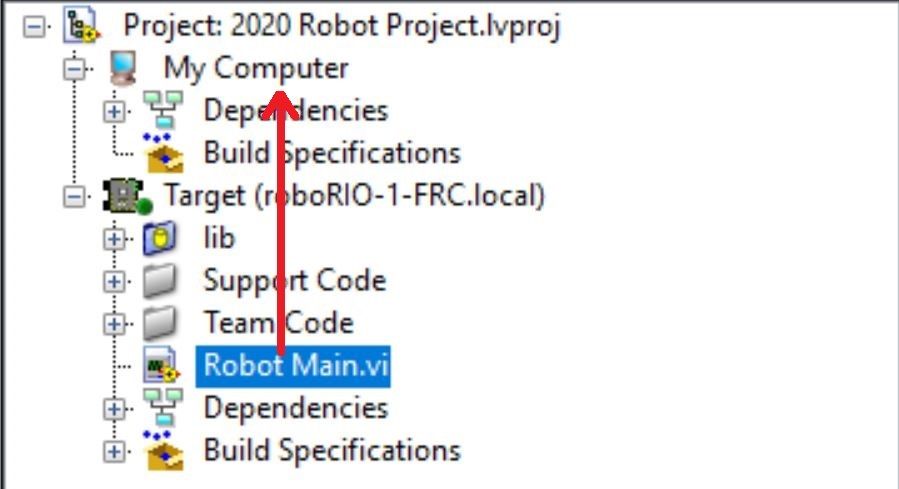

The subsystem implementation and commands for the robot drive base. The items that define operation on the roboRIO located at (address).

#First robotics labview programming tutorial how to#

This will contain the files that define how to build and deploy code for the simulated robot target. This will populate when you designate the code for the simulated robot target. Shows the files used by the simulated robot’s code. Robot Simulation Readme.htmlĭocuments the PWM channels and robot info you will need in order to write robot code that matches the wiring of the simulated robot. The folder containing 3D CAD models and description files for the simulated robot. For a robot project, this is used as a simulation target and is populated with simulation files. The items that define operation on the computer that the project was loaded on. The most frequently used items have been bolded. Below is a description of the major components in the Project Explorer to help with the expansion of our system. The Project Explorer provides organization for all of the Vis and files you will use for your robot system. Because each command is a VI, you are able to single step through commands or use the built in Trace functionality to view a list of all commands sent to each subsystem.The framework uses asynchronous notification and consistent data propagation making it easy to program a sequence of commands or add in simple logic to determine the correct command to run. I/O encapsulation makes for more predictable operation and quicker debugging when resource conflicts do occur. If physical changes are made to the robot, such as changing a gearing ratio, changes can be made to just a few command Vis to reflect this change across the entire code base.

#First robotics labview programming tutorial update#

The commands themselves are VIs that can update set points, perform numerical scaling/mapping between engineering units and mechanism units, and offer synchronization options. Subsystems are used to abstract the details of the implementation, and game code is built from sequences of high level command VIs.

#First robotics labview programming tutorial driver#

For teleOp, the same commands can execute asynchronously, allowing the robot to always process the latest driver inputs, and if implemented properly, new commands will interrupt, allowing the drive team to quickly respond to field conditions while also taking advantage of automated commands and command sequences.Ĭommand and Control adds functionality to the existing LabVIEW project templates, allowing code to scale better with more sophisticated robots and robot code. Commands can be wired sequentially with additional logic to quickly build complex routines. For Autonomous, it is very common to define the robot’s operation as a sequence of operations – drive here, pick that up, carry it there, shoot it, etc. Game code, primarily consisting of Autonomous and TeleOp, will typically need to update set points and react to the state of certain mechanisms. It also becomes easier to add an additional sensor, change gearing, or disable a mechanism without needing to modify code outside of the controller. This speeds up debugging a robot behaving unexpectedly by giving you the ability to look through a list of commands sent to the subsystem rather than searching your project for where an output may have been modified. The difference is very subtle but this means that outputs can only possibly be updated from one location in the project. Code outside of the subsystem controller can issue commands which may change the robot’s output, but should not directly change any outputs.

One of the key principles of this framework is that subsystems will each have an independent controller loop that is solely responsible for updating motors and other actuators. Each of these is referred to as a subsystem and needs code that will coordinate the various sensors and actuators of the subsystem in order to complete requested commands, or actions, such as “Close Gripper” or “Lower Arm”. Command and Control recognizes that FRC robots tend to be built up of relatively independent mechanisms such as Drive, Shooter, Arm, etc.

0 kommentar(er)

0 kommentar(er)